Board-form concrete – How to know what’s good

Board form concrete can be a breathtaking and artistic architectural effect. Simply, it’s a way to use concrete as a building material, but with the added beauty of featuring a real wood grain pattern. When forming a board-formed concrete wall, for example, forms are built so that the horizontal 6” board lines, or vertical board lines, as well as the wood grain is touching the concrete when poured. Once the forms are removed, the pattern remaining is visually stunning.

Vertical boards make a design feel taller, narrow board widths accentuate directionality, so that vertical orientation seem taller and horizonal boards seem longer. The contrast of the vertical wood design and horizontal board design used here, delivers a stunning effect.

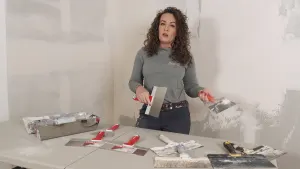

Board forming is an old technique that pre-dates the large panelized systems used today. The forming method combines concrete's inherent plasticity with all of the imperfections of wood—the knots, gaps, and grain. Doing it right, however, takes a slow and methodical approach to building the forms, often taking two to three times longer than traditional form-building.

Strong bracing is critical to handle the pressure that the forms will take with the heavy concrete. Form ties used for this design should be made of fiberglass rather than steel. Once the formwork is created and locked together with screws the inside corners are mitered. To ensure a smooth appearance where the surface imperfections are visible and to avoid slump, a plasticizer should be added to the concrete.

One of the most important steps is to vibrate the concrete, moving from the bottom of the pour upwards, once it is poured into the forms. This consolidates the concrete and goes a long way to avoiding substantial honeycombing.

The challenges—what can possibly go wrong?

What is a good result? Ultimately, that’s tied to the expectations that were established at the onset. Often, failure is based on cracking and honeycombing of the concrete. What can go wrong and how to avoid it includes:

- Concrete seepage between individual boards—use a bead of silicone when joining the edges.

- Too much honeycomb—vibrate, but don’t vibrate so much you’ll bring aggregate to the top.

- Form ties rusting and too visible—use fiberglass ties rather than steel.

- Corner edges that break—use a small chamfer to cast a shadow line that looks like a hard-edged corner.

- Cracking—use control joints to minimize the potential for cracking.

- Not sure which wood to use—Douglas Fir is always a great choice.

- Inexperience of concrete contractor—make sure to see samples of work and talk to customers.

The higher expense of board-form concrete is based on the fact that its aesthetics are ultimately very important. To get that right, the cement contractor should have a focus on delivering pretty finish work and being concerned with what the client wants to achieve, rather than pouring a basement foundation in record time. When aesthetics meet the client’s expectations, it’s a good job.

Setting expectations

Unfortunately, board-form concrete is a process where achieving perfection is extremely difficult. It is common for contractors to bid board-form jobs at double the cost of a regular concrete pour, since there is always a risk of having to tear it down and start again. Success depends as much on precise carpentry as concrete capabilities. Not only should some imperfection be expected, it can actually add to the attractiveness of the results.

Board-formed concrete delivers drama and life to wall surfaces and complements other wood textures used.

Wabi-sabi, the beauty of imperfection

In Japan, wabi-sabi translates to imperfect, impermanent and incomplete. This view accepts imperfection in art, building, virtually anything creative. A little imperfection, therefore, is okay in a board-formed concrete project, as long as it remains visually appealing. Most imperfections seen in board-form concrete from the homeowner’s and contractor’s perspectives, disappear in time and just aren’t seen.

Although the expense can be high, board-form concrete delivers a breathtaking and artistic signature on the design of a home. Whether used for interior walls or a retaining wall, it provides extreme beauty and a strong architectural element.

One thing our experience has taught us, there are big differences between well done board formed concrete and average or poorly done projects. Since all board formed walls have imperfections, make sure you have seen your contractors past efforts, and that you and the contractor agree on the desired result.

Share on facebook

Share on facebook Tweet

Tweet Email

Email Share on Linkedin

Share on Linkedin