Proper Site Conditions Before Wood Floor Installation

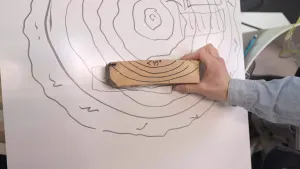

Wade is getting ready to install a four-inch white oak floor, but first, he needs to make sure that conditions are just right on the jobsite.

Monitoring of conditions includes the time prior to arrival, at the time of arrival, and during installation. What you'll be looking for is humidity. Most flooring comes from the mill at a 6 to 8% moisture level. This number can increase during transport. Before flooring arrives, make sure your relative humidity is dialed in at ideally 30 to 40%. Make sure you're checking your subflooring (Wade uses Advantech so he doesn't see much moisture, typically).

Remember that moisture content is directly related to relative humidity. Monitor temperature and relative humidity with a moisture meter to check subfloor and flooring materials.

A good flooring installer makes sure the materials coming from the mill are in optimal conditions and checks/documents the data for a few days before installation.

Wade also uses a moisture barrier roll-on over subfloors on first floor that are over basements or crawl spaces, replacing the tar paper or rosin paper function.

You do not need to wait two weeks to install as some of you may have heard, you just need to monitor your conditions to make sure they are ideal and you can begin installing.

Share on facebook

Share on facebook Tweet

Tweet Email

Email Share on Linkedin

Share on Linkedin